Analysis Tutorial 1: Basic Analysis and Templates 1

This tutorial showcases some of the basic functionality of EMDtool, including

* Creating a motor model from templates * Running time-static analysis and post-processing basic results

Contents

Setting dimensions

First, let us set the dimensions required. For simplicity, we begin by initializing an empty structure.

Finally, let us initialize a timer to see how long stuff actually takes:

tic;

addpath(genpath('../EMDtool'));

dim = struct();

Next, let's set some general dimensions and specs.

%general dimensions dim.p = 10; %number of pole-paits dim.Qs = 24; %number of stator slots dim.delta = 1e-3; %total effective airgap dim.leff = 70e-3; %core length dim.temperature_rotor = 100; dim.temperature_stator = 120;

Then, let us define our winding.

%winding parameters

winding = ConcentratedWindingSpec(dim);

winding.N_layers = 2;

winding.filling_factor = 0.5;

winding.N_series = 12;

dim.stator_winding = winding;

dim.symmetry_sectors = dim.stator_winding.symmetry_period();

Furthermore, let us set some general dimensions. These help the templates to determine whether we are making an inrunner or an outrunner motor.

dim.Rout = 50e-3; %airgap-side radius of rotor dim.Sin = dim.Rout - dim.delta; %airgap-side radius of stator dim.Sout = 28e-3; %frame-side radius of stator

Finally, let's specify the materials used. For the default materials available, check out here.

dim.magnet_material = 14; %Magnet material dim.rotor_core_material = 4; %rotor iron material dim.stator_core_material = 4; %stator core material dim.stator_wedge_material = 0; %air; no wedge

Creating rotor geometry.

Now, let's set some more dimensions.

%rotor dimensions dim.hyr = 5e-3; %rotor yoke thickness dim.h_sleeve = 0e-3; %no retaining sleeve for PMs dim.hpm = 3e-3; %PM thickness dim.alpha_pm = 0.8; %PM pitch, relative to pole pitch dim.is_halbach = false; %no Halbach array

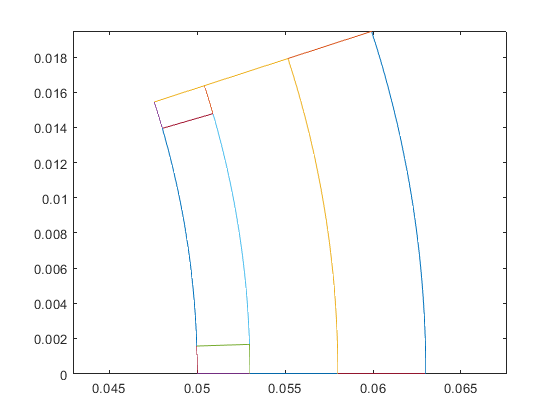

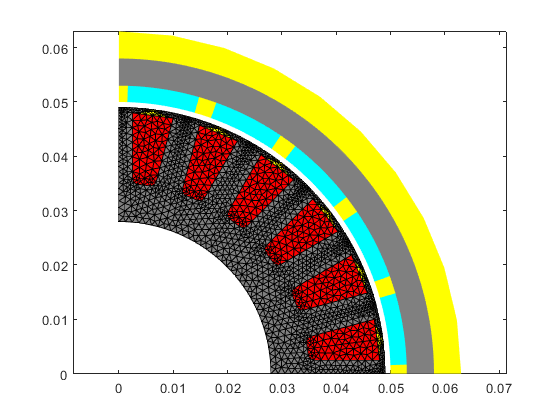

...and create and plot the geometry:

rotor = SPM1(dim); figure(1); clf; hold on; box on; axis equal; rotor.plot_geometry(); snapnow;

Creating stator geometry.

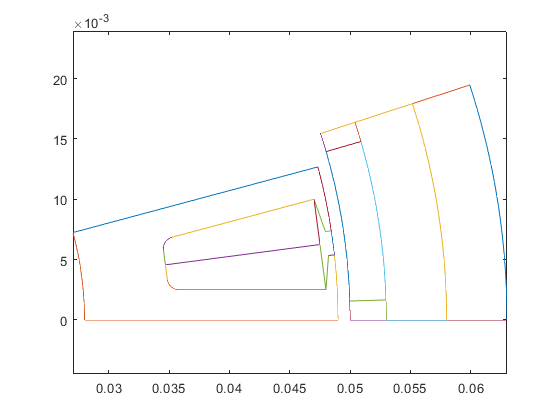

Next, let's do the same for the stator. There are oly a few more dimensions to set.

%stator dimensions dim.htt_s = 1e-3; %tooth tip height dim.htt_taper_s = 0.5e-3; dim.hslot_s = 14e-3; %total slot depth, airgap to bottom dim.wtooth_s = 5e-3; %tooth width dim.wso_s = 2e-3; %slot opening width dim.r_slotbottom_s = 1e-3; %slot bottom fillet radius dim.stator_stacking_factor = 0.99;

Create the geometry, and plot it.

stator = Stator(dim); figure(1); stator.plot_geometry(); snapnow;

Meshing the geometry

Pretty self-evident, huh?

stator.mesh_geometry(); rotor.mesh_geometry(); figure(2); clf; hold on; box on; axis equal; stator.visualize('linestyle', '-'); rotor.visualize(); snapnow; toc

Elapsed time is 2.129119 seconds.

Creating a Model

Now, we create a model, an object for encapsulating all the relevant components, aspects, and behaviour of our design. Since we are dealing with a rather standard radial-flux motor, the base class RFmodel will do.

tic; motor = RFmodel(dim, stator, rotor);

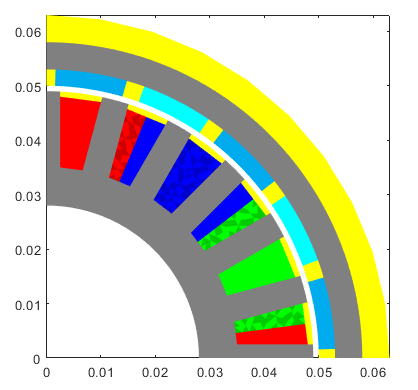

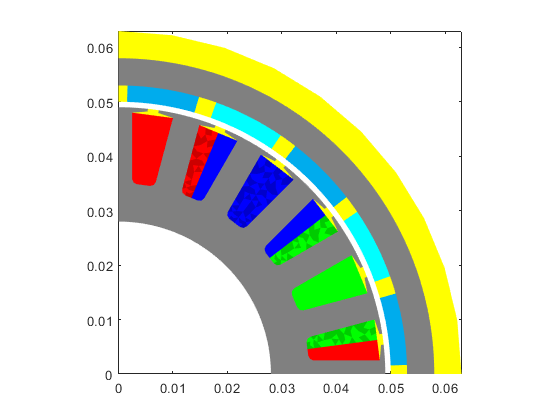

For reasons, let's also visualize the model to see e.g. the winding layout highlighted with different colours.

figure(2); clf; hold on; box on; axis equal; motor.visualize(); snapnow;

Let's also create a MagneticsProblem object for representing the problem we're analysing.

problem = MagneticsProblem(motor); toc;

Elapsed time is 0.377287 seconds.

Setting supply

For now, we're going to be using a current supply model, meaning we're not taking induced voltages etc. into account.

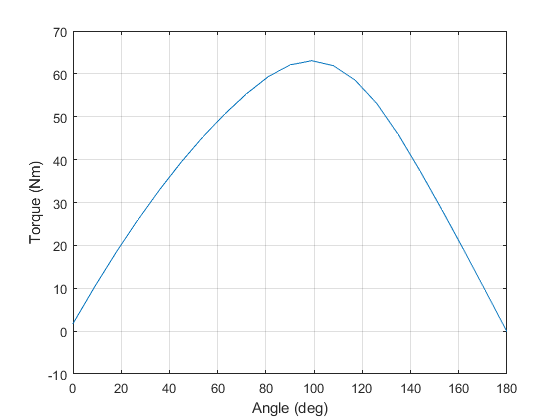

Let's run a sweep of load angles from 0 to 180 degrees, to compute a rough torque curve. First, create an array for the load angles

tic;

load_angles = linspace(0, pi, 21); %load angles to analyse

Then, do an inverse Park-Clarke transformation to get the instantaneous phase currents from the dq-components:

Is = xy(80*[cos(load_angles); sin(load_angles)], problem)

Is = Columns 1 through 7 77.2741 73.0836 67.0936 59.4516 50.3456 40.0000 28.6694 -20.7055 -8.3623 4.1869 16.6329 28.6694 40.0000 50.3456 -56.5685 -64.7214 -71.2805 -76.0845 -79.0151 -80.0000 -79.0151 Columns 8 through 14 16.6329 4.1869 -8.3623 -20.7055 -32.5389 -43.5711 -53.5304 59.4516 67.0936 73.0836 77.2741 79.5618 79.8904 78.2518 -76.0845 -71.2805 -64.7214 -56.5685 -47.0228 -36.3192 -24.7214 Columns 15 through 21 -62.1717 -69.2820 -74.6864 -78.2518 -79.8904 -79.5618 -77.2741 74.6864 69.2820 62.1717 53.5304 43.5711 32.5389 20.7055 -12.5148 0.0000 12.5148 24.7214 36.3192 47.0228 56.5685

Set the current array as source current...

C = motor.circuits.get('Phase winding'); C.set_source('uniform coil current', Is);

Running analysis

...and solve a series of static problems.

pars = SimulationParameters('rotorAngle', 0*load_angles/dim.p, 'silent', true); solution = problem.solve_static(pars);

Plotting results

Finally, plot the torque curve and the flux density at peak torque.

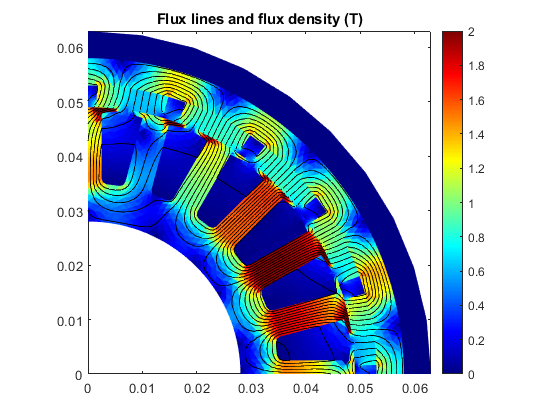

T = motor.compute_torque(solution); figure(6); clf; hold on; box on; grid on; plot(load_angles/pi*180, T); xlabel('Angle (deg)'); ylabel('Torque (Nm)'); snapnow toc figure(7); clf; hold on; box on; motor.plot_flux( solution, 11);

Elapsed time is 1.751505 seconds.